*Directive 2014/34/EU entered into force in February 2014. EU Member States should take all necessary measures to ensure that products covered by this Directive appear on the market and are put into operation only if they meet its requirements. This refers to the situation when the products are properly installed, receive competent maintenance and are used for their intended purpose.

Scope of application

The Directive applies to the following products for use in an explosive environment:

1. Equipment and protective systems that are intended for use in explosive zones

2. Protective devices, control devices and regulating devices that are intended for use outside potentially explosive environments, but which are necessary for the safe operation of equipment and protective systems or reduce the risk of explosion

3. Components intended for inclusion in equipment and protective systems that have already been specified in paragraph 1

Equipment refers to various machines, equipment, stationary or mobile devices, components of control and monitoring devices, detection and warning systems. Together or separately, they are designed for the production, transmission, storage, measurement, control and conversion of energy, as well as for the processing of materials that can provoke an explosion due to their own potential ignition sources.

Protective systems are devices (other than equipment components) that are designed to instantly suppress an explosion or limit the radius of damage and that are used as autonomous system devices.

Components are any elements of equipment and protective systems that are necessary for their safe operation. They are not intended for independent use.

Explosive atmosphere is a mixture of air with various combustible substances (gases, vapors, fog, dust). It occurs under atmospheric conditions, and in the case of ignition, gorenje spreads to its entire volume.

The Directive does not apply to the following products:

– Medical devices

– Equipment and protective systems, the risk of explosion of which is associated only with the presence of explosives or unstable chemicals

– Equipment that is intended for use in domestic and non-industrial conditions, where a potentially explosive atmosphere occurs extremely rarely and exclusively as a result of accidental leakage of gaseous fuel

– Personal protective equipment in accordance with European Union Directive 89/686/EEC of 12/21/1989

– Marine vessels and marine mobile installations, including equipment on board

– Vehicles and vehicles towed by them, intended exclusively for the carriage of passengers by air, water, roads or railways. However, vehicles intended for use in potentially explosive atmospheres are subject to the Directive

– Products specified in paragraph b of article 34b of the Treaty on the Functioning of the European Union

Product Requirements

The products must comply with the basic safety and health requirements. These requirements are set out in Annex II to the Directive.

The Directive contains the responsibilities of the so-called economic entities: the manufacturer, the manufacturer’s representative, the importer and the supplier. Their first duty is to ensure that the products have been designed and manufactured in accordance with the basic health and safety requirements set out in Annex II.

Technical documentation must be compiled for the products, which is specified in Annexes III to IX.

The manufacturer must carry out the appropriate conformity assessment procedures listed in Article 13, or instruct them to carry out.

For products (except components) that have passed the conformity assessment, an EC declaration must be drawn up and the CE marking must be applied, and, where applicable, also other markings and information specified in paragraph 1.0.5 of Annex II of the Directive.

Conformity assessment procedure

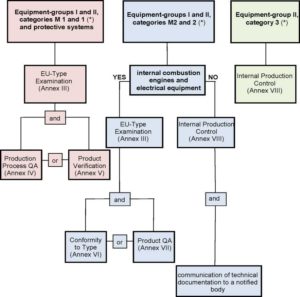

The following conformity assessment procedures are provided:

1.Equipment of groups I and II of category M 1 and 1 passes type tests (module B) in combination with one of the following methods:

– Type compliance based on quality assurance of the production process (Module D)

– Type conformity based on product verification (Module F)

2. Equipment of groups I and II of category M 2 and 2:

(a) Internal combustion engines and electrical equipment undergo type tests (set out in Annex III) in combination with one of the following methods:

– Type compliance based on internal production control and controlled product testing (Module C1)

– Type compliance based on product quality assurance (Module E)

b) The rest of the equipment in these groups and categories is controlled by internal production (Module A). The technical documentation is transferred for storage to the authorized body

– Equipment from Group II belonging to category 3 undergoes internal production control (Module A)

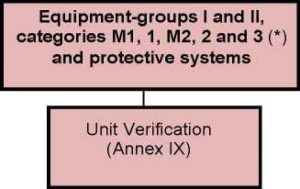

– Equipment of groups I and II, in addition to the procedures listed in the preceding paragraphs, can also undergo conformity assessment based on unit verification (Module G)

– Protection systems are assessed for compliance according to the procedures specified in paragraphs 1 and 4

– The components undergo conformity assessment according to the procedures specified in paragraph 1. The manufacturer issues a written confirmation of conformity for them and indicates their characteristics, as well as describes how these components should be included in equipment or protective systems

| Conformity assessment procedure | Short description |

|---|---|

| EU-type examination (Module B) | Provides a specimen of the envisaged production to a notified body which undertakes the necessary evaluation to determine that the "type" meets the essential requirements of Directive 2014/34/EU and issues an EU-type examination certificate. |

| Conformity to type based on quality assurance of the production process (Module D) | Operates a quality system approved by a notified body for production, final equipment inspection and testing, subject to on-going surveillance. |

| Conformity to type based on product verification (Module F) | Examination and tests by a notified body of every product to check the conformity of the equipment, protective system or device with the requirements of Directive 2014/34/EU and draw up a certificate of conformity. |

| Conformity to type based on internal production control plus supervised product testing (Module C1) | Tests carried out by a manufacturer on each piece of equipment manufactured to check the explosion protection aspects of the design. Carried out under the responsibility of a notified body. |

| Conformity to type based on product quality assurance (Module E) | A quality system approved by a notified body for the final inspection and testing of equipment, subject to on-going surveillance. |

| Internal production control (Module A) | Product and quality system assessment procedure carried out by the manufacturer and retention of documentation. |

| Conformity based on unit verification (Module G) | A notified body examines individual equipment or protective system and carries out tests as defined in European harmonized standards, if they exist, or otherwise in European, international or national standards or conduct equivalent tests to ensure conformity with the relevant requirements of Directive 2014/34/EU and draw up a certificate of conformity. |

| Internal production control plus communication and retention of technical documentation by a notified body | Product and quality system assessment procedure carried out by the manufacturer and retention of documentation by a notified body. |